Mineral processing / hydrometallurgical test center

Specialized in the processing of minerals containing technology metals associated with NORM (Naturally Occurring Radioactive Material). Reproducible sample preparation is ensured by crushing, grinding, sieving, homogenization and mechanical beneficiation (gravimetric, magnetic) with the most modern lab instruments in order to facilitate a reliable sample analysis. The geochemistry is determined by XRF and additional analyses such as ICP-MS/AES, SEM or MLA/QEMSCAN. Generally, the facilities of the technical center provide contamination-free and reliable sample preparation; optimized and certified for NORM samples. Industrial (hydro)-metallurgical processing options are investigated from lab- to pilot-scale and are simulated by chemical processing models for up-scaling.

To request more information and prices call +49351-8864600 or e-mail us: info@uit-gmbh.de.

More information

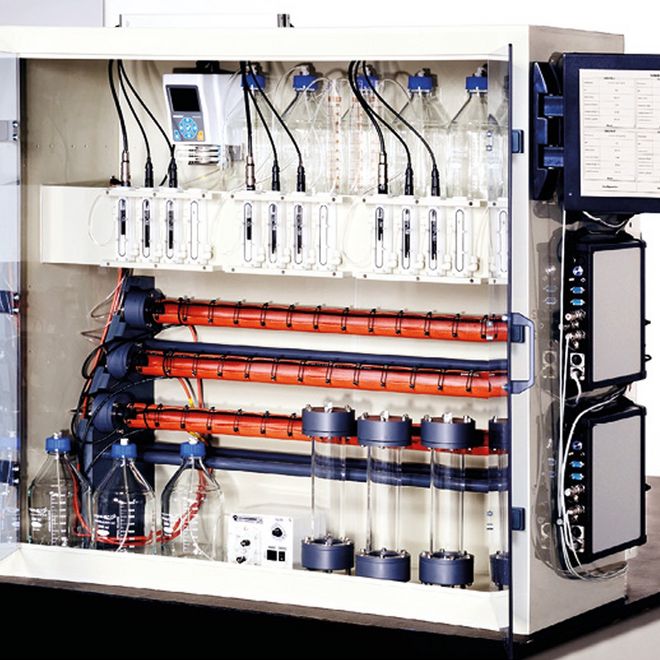

(Dynamic) column leach test facility ((D)CLTF)

The column leach test facility (saturated flow) is designed according to international standards, operating a 3-channel system with either horizontal or vertical flow. Operational parameters corresponding to realistic ISR wellfield conditions (aquifer temperature, pore volume exchange rate) monitored by real-time data logging/control.

- Anaerobic column preparation (N2)

- 3-channel high-precision peristaltic feed pump

- 3-channel temperature control

- 3 parallel columns (horizontal or vertical)

- In-line measurement of pH, ORP, EC, (I), p

- Injection leachant reservoirs

- Leachate collectors for sampling

- DCLTF allows use of intact and undisturbed drill core samples and various sizes (NQ, HQ, PQ)

Heap/tank leaching

Percolate column leach tests are performed under ambient physical conditions in order to simulate heap leaching. Performance depends on chemical parameters, unsaturated flow conditions and additional parameters (e.g. particle size distribution, homogeneity, porosity). Test results enable up-scaling of an ideal reactive transport model to real-world scenarios.

Services

- Crushing, grinding and sieving

- Sorting (magnetic separation, gravity separation, flotation)

- Solid-liquid separation

- Consulting, process optimization

- Mineral and chemical analyses incl. NORM by ore microscopy, XRF and Raman

- Process design and basic engineering

- Heap leaching

- In-situ recovery

Request now

Do you have questions about delivery times, technical details or the realisation of individual systems & solutions?

Contact us! A member of staff will deal with your request and answer it promptly.

You can reach us by telephone at

+49 351 886 4600

Or by e-mail to

info@uit-gmbh.de