Radioactively contaminated wastewater can be generated from historic uranium mine and mill sites by various mechanisms or the combination of those. This could also apply to technology metal deposits (e.g. rare earth ore formations) containing NORM (naturally occurring radioactive material) due to the significant abundance of Th and/or U. Examples for the mobilization and transport of NORM in mine and mill site environments include:

1. Mine development => groundwater draw-down/de-watering => oxidation => mine flooding

2. Seepage from tailings ponds, waste rock heaps (in particular, from those without protective coverage)

3. Waste streams from ore processing and metal extraction in general

The composition of NORM containing wastewater could vary significantly regarding acidity/alkalinity (pH), element concentrations of (heavy) metals, alkaline earth metals, complexing ions, halides, and, in particular, radioactive elements (U and Th isotopes and all progenies of the relevant decay chains). Usually, the secular equilibrium of radioisotopes in original formations is radically disturbed in radioactive wastewater due to the separating chemistry of its generation.

Accordingly, the treatment of NORM contaminated wastewater is site specific and needs to be developed or adapted to the application case, in particular, regarding the removal of radioactive constituents, to meet regulatory requirements. Both NORM mobilization and wastewater chemistry could significantly vary in time, thus, requiring a high dynamic range of treatment technology and, in particular cases, the upgrade for a long-term operation under essentially changed inflow conditions (typically depleting).

Unique model/software development to simulate NORM mobilization and wastewater chemistry, e.g. in the case of flooding uranium mines (specific 3D-compartment reactive transport approach including NORM)

By combining the hydrologic dynamics of mine flooding with the very detailed geochemical processes (including the redox transition from oxidative conditions in open mineworks towards reducing conditions in saturated rock formations; also considering active in-situ remediation by dosing reagents), the flooding process can be reproduced and optimized in a controlled manner to minimize environmental impacts. The model predicts the (time-dependent) composition of flood water to be treated, enables the optimization of technology including flood control and adaption to changing conditions, and provides essential input to permit procedures.

U removal from highly contaminated flood water (application: Wismut site Koenigstein)

Wismut’s former U mine at Koenigstein was exceptional. After conventional mining Wismut introduced the acidic in-situ leaching technology in underground mineworks (block leaching). The remediation of the mine required a controlled flooding combined with the collection and treatment of the flood water. A specific technology of U removal (ion-exchange IX combined with industrial-scale IX chromatography to separate abundant Fe; patented) and processing to a salable product has been implemented in 1997 and operated until 2021. Due to the high dynamic range of U removal efficiency the plant was capable to cope with U concentrations in the flood water up to ca. 250 ppm (maximum in 2002).

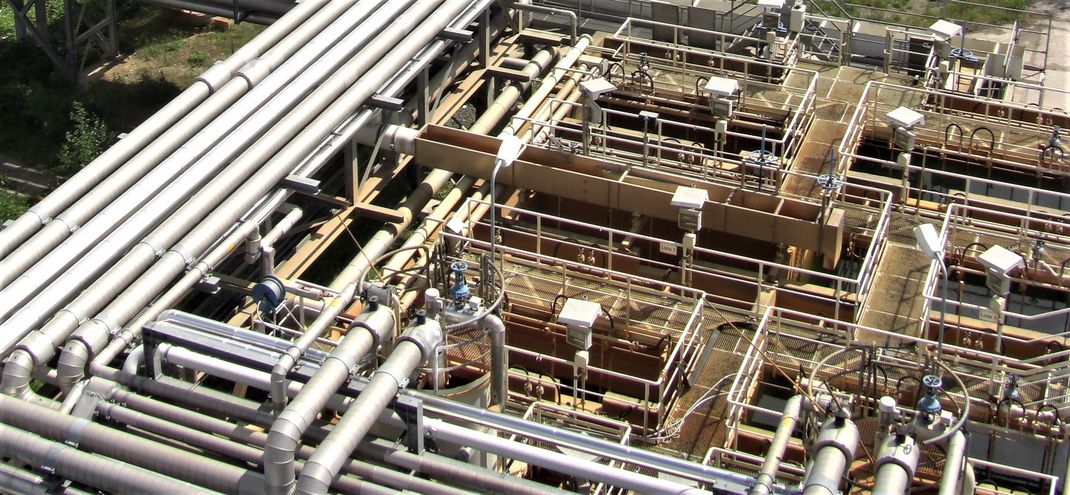

Flood water treatment by a modified high-density sludge (HDS) technology (applications: Wismut sites Koenigstein and Ronneburg)

An advanced HDS technology (multi-stage neutralization with partial sludge recycling, Ra removal; patented) has been developed to clean the contaminated flood water under changing feed conditions reliably and to produce a chemically and geotechnically stable solid waste for safe disposal. The HDS plant at Koenigstein has recently (2021) been upgraded to improve its efficiency and flexibility after decommissioning the U removal plant described above. The flood water treatment at Wismut’s Ronneburg site (complex of 14 interconnected individual mines) is a combination of de-carbonization (acidification) and subsequent HDS technology.

Long-term seepage water treatment from uranium tailing ponds (application: Wismut site Helmsdorf)

The original treatment technology (based on lime neutralization) has been substituted by a more efficient and economic alternative (completed in 2021). It is a combination of IX (U removal) and adsorption by granular iron hydroxide (As removal).

Additional applications

The special technologies developed for the efficient treatment of NORM-contaminated wastewater from Wismut applications have been generalized and meanwhile adapted to several international projects including similar remediation cases, U mining/processing and recovery of technology metals including rare earth elements.

https://www.imwa.info/docs/imwa_2008/IMWA2008_157_Braun.pdf

https://link.springer.com/chapter/10.1007/3-540-28367-6_24

https://www.imwa.info/docs/imwa_2002/imwa_2002_1037-1044.pdf