BTP2 - control - Automatic biogas test plant

BTP2 - control - Automatic biogas test plant

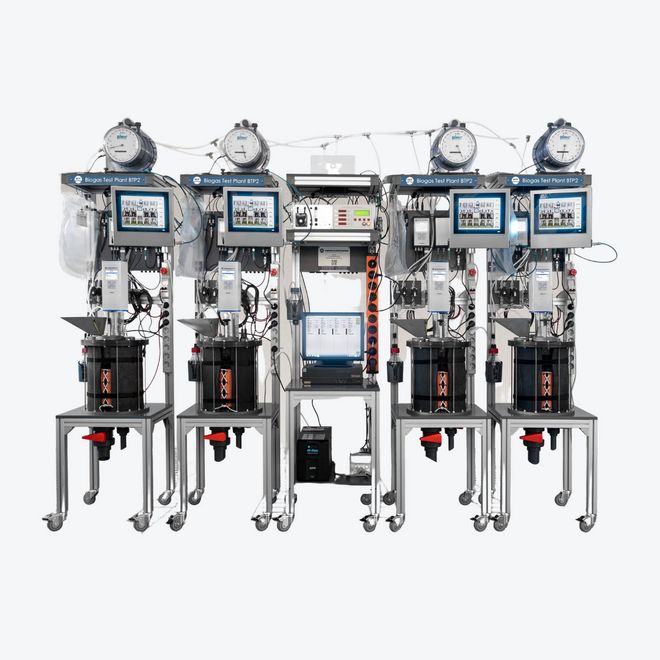

The BTP2 control biogas test system is equipped with gas analyzer (CH4; CO2; H2S; O2 and optional H2) in addition to the extensive basic measurement technology of the BTP2 (pH; gas volume; temperature and optional redox potential). This integrated gas analyzer is used automatically for several reactors one after the other. For the analysis, the gas is collected in gas bags and the gas analysis is carried out automatically for the individual reactors when a sufficient quantity of gas has been collected.

Even the smallest gas volume flow can be reliably recorded and analyzed. This system can be combined with the AS2 pump modules and autosampler from UIT, it is characterized by a high degree of equipment and automation. The BTP2 control biogas test plant is used in particular in the scientific field but also for substrate and gas yield tests in other fields of application.

This system is perfect for product development (enzymes, nutrients) and process optimization.

For additional information and prices, please call +49 351 886 4600 or use our E-Mail: info@uit-gmbh.de.

More information

Product characteristic

- Bioreactors, volume 15 liters, different volumes on request

- Continues operation with AUTO feeding (Optional)

- Electric heating with control

- Dosage pumps for pH-value control (Optional)

- Powerful agitators with two stirrers

- Gas meter to measure gas quantity

- Gas Quality Measurement (CH4, CO2, H2S, O2)

- Central data acquisition

- Bio reactor with various installation ports

- Silicon – heater band

- Feeding system

- Stirrer including speed adjustment and display of torque

- Gas tight shaft feed

- Gas bag for gas sampling

- Assembly frame

- Measuring equipment (pH-Value / Redox-Potential (Optional) / temperature)

- T-Controller device

- Temperature measuring equipment

- Redox measuring equipment

- Recording of gas quantities through gas meters

- Automatic gas analysis system

- Software package Biogas-control

Area of application

- Research

- Fermentation yield test

- Optimization of gas outout

Advantages

- On-line measuring equipment

- System expandable up to 10 reactor units

- Integrated gas analysis

- Data storage and visualization

- Simultaneous recording of gas quality and quantity

- Central data acquisition and control unit

- Customized equipping and automation-degree

- Compact, space-saving rack systems

Technical Data

| Bioreactor with Measuring Technique and Stirrer | |

|---|---|

| Measuring Equipment for Bioreactor | |

| Stirrer / Stirrer features | |

| Gas Counter / Gas Bag | |

| Gas Quality Measurement System | |

| SENSOcontrol | |

| Software Features | |

| Space Requirements | |

| Dimensions | Vol. approx. 15 liter; outer diameter: 270 mm, wall thickness: 9 mm, height: 350 mm; differnt volumes on request |

| Material / Configuration | For measuring equipment |

| Max. allowed Temperature | 60°C |

| Feeding | Feeding funnel (stainless steel) including dipped duct and sealing plug |

| Shaft feed through | Variant 1: dipped duct |

| Variant 2: surge tank | |

| Heating | Silicon-heater band incl. temperature sensor, Height of heater band: 200 mm; max. input power for heating: 500 W Adjustment of heating system through T-control unit |

| pH-value | Measuring range: 1-14; Length: 220 mm, PG 13.5 screw-in thread |

| Redox potential (ORP) | Option: Measuring range: - 2000...+2000 mV; length: 220 mm, PG 13.5 screw-in thread |

| Temperature | Measuring range: 0...60°C, resolution: 0.1 °C, sensor screwed-in |

| Speed range | 10 – 500 rpm |

| Torque | Max. 600 Ncm |

| Display | Speed and torque |

| Stirrer tools | 2 levels with propeller shaped stirrers and anchor shaped stirrers |

| Measuring range | 1…60 l/h; resolution: 2,5 ml |

| Gas Bag | Volume 10 liter as sample for gas quality measurement |

| CH4 | Range: 0...100 Vol. %; measuring principle: IR |

| CO2 | Range: 0...100 Vol. %; measuring principle: IR |

| H2S | Range: 0...5000 ppm; principle: electro-chemical - one range |

| O2 | Range: 0...25 Vol. %; principle: electro-chemical measuring cell |

| Features | Gas cooler |

| Storage and Display Unit | pH-value, temperature and gas amount – incl. graphical and tabular display of actual values |

| Control Values | Asynchronous timing of the agitator Option: pH control using of several 2-channel peristaltic pumps |

| Software | Biogas-control |

| Modules | Width: 50 cm; Depth: 65 cm; Height: 240 cm – for each module |

| Zcentered Gas Quality Measurement Modul with PC | Width: 115 cm; Depth: 65 cm; Height: 240 cm |

Illustrations and descriptions may vary. The plant / product is subject to change depending on technical updates.

We will gladly give you an individual offer.

Downloads

Request now

Do you have questions about delivery times, technical details or the realisation of individual systems & solutions?

Contact us! A member of staff will deal with your request and answer it promptly.

You can reach us by telephone at

+49 351 886 4600

Or by e-mail to

info@uit-gmbh.de