Flushing Water

Treatment of flushing waters from internal material cycles to reduce disposal costs, or recycling of consumables

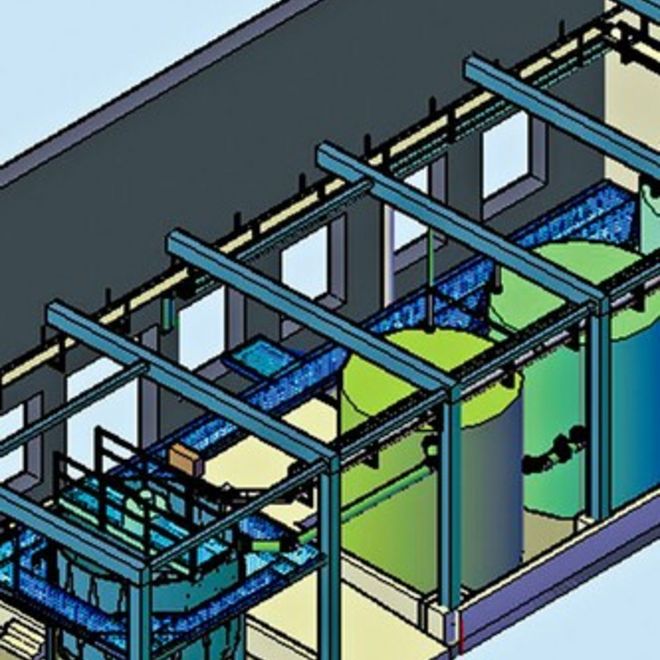

Many industrial fields in the steel and automotive industry yield flushing water contaminated by cooling and lubrication ingredients, or other oil and grease substances. We offer fieldapproved solutions for concentration and treatment of flushing water streams.

The foci of process engineering include separation of solids, phase separation and the subsequent stages of concentration. Thermal or membrane-based technologies (ultrafiltration) are proved and tested concentration methods.

The setup of peripheral plant components such as storage- or decanting facilities for handling and disposal of waste oil and coolants/lubricants, as well as exhaust treatment (biofilters, adsorbents and scrubbers) are additional services offered in our range of competencies.

We also modernize your existing plant or construct new plants fitted to your existing production interfaces. One main focus is the integration of modern, effective process steps, replacement/incorporation of existing testing methods and/or replacement of outdated switchgear/control systems.

When planning the modernization, or design of a new-built plant for flushing water processing, we focus on the required dimensioning and equipment components of the plant according to current water and construction regulations and constraints, including Federal Immission Control Act (BlmSchG).

Request now

Do you have questions about delivery times, technical details or the realisation of individual systems & solutions?

Contact us! A member of staff will deal with your request and answer it promptly.

You can reach us by telephone at

+49 351 886 4600

Or by e-mail to

info@uit-gmbh.de